3/29/19

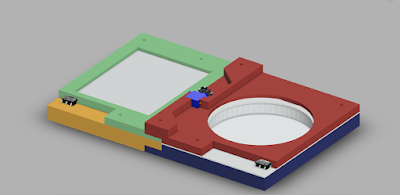

ARHAB Blog 3/29/19 - Add Clearance (1/2mm-1mm) to top and bottom where components meet - Increase height of treads on door/Print better gear - Possibly combine two larger components into one - Add additional two switches and add holes for mounting and (1.5mm-2mm of travel to engage switch) - UChannel for feeding wires to circuit board? - Extend end so the door doesn't need to close at the perfect spot Latest Design: