Week 4, Monday

General

Professor Griffo and Ian looked over and updated the 2016 checklist so that it applies to our current project. It includes everything we need and directions for launch. We still need to go over the checklist to make sure we still have everything in the toolbox or if we need anything else.

We are also deciding on the parameters for the upcoming tethered flight.

Additionally, the models of the camera housing and casing assembly presented a clipping issue in Fusion 360. This was resolved by removing 1.8 mm from the inner right wall of the back part of the assembly. Similar to the front part of the assembly, it may be faster and cheaper to incorporate the change into the physical copies by sanding the removed portions away.

The code for logging the data has been completed. The complete circuit board has been assembled and we started testing all the components.

We are also trying to figure out how to accurately read altitude via the onboard GPS devices. That said, we may need to renew our subscription for the Spot GPS services.

We discussed general issues and status updates regarding the subdivisions of the HAB Team. One of the topics discussed was the risks to the electronics onboard the payload on landing as well as the risks to ourselves depending on where it falls.

On a similar note, we set up accounts and channels for Slack to improve communication between teammates.

On a similar note, we set up accounts and channels for Slack to improve communication between teammates.

Professor Griffo and Ian looked over and updated the 2016 checklist so that it applies to our current project. It includes everything we need and directions for launch. We still need to go over the checklist to make sure we still have everything in the toolbox or if we need anything else.

We are also deciding on the parameters for the upcoming tethered flight.

CAD

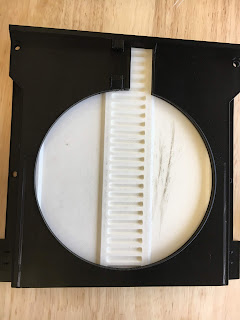

We refined the newer print of the lid to reduce its thickness and width. These issues were likely because of the slicing software and/or printer rounding to the wrong measurements. We sanded down the sides of the lid in addition to reprinting the component with reduced layer thickness. The sanded copy now slides in and out of the rim with little to no resistance.

Additionally, the models of the camera housing and casing assembly presented a clipping issue in Fusion 360. This was resolved by removing 1.8 mm from the inner right wall of the back part of the assembly. Similar to the front part of the assembly, it may be faster and cheaper to incorporate the change into the physical copies by sanding the removed portions away.

Circuits

The code for logging the data has been completed. The complete circuit board has been assembled and we started testing all the components.

We are also trying to figure out how to accurately read altitude via the onboard GPS devices. That said, we may need to renew our subscription for the Spot GPS services.

Cameras

We discussed possible camera mounting solutions, which include using a different casing system entirely.

Comments

Post a Comment